GT and the Inner Tensions of Metals

Working with scientific institutes over the last few years has heightened our sensitivity towards the expectations concerning our galvanic layers.

Besides hardness, ductility, electric conductivity, and other specifications customers often wish for particularly even layers.

This is very understandable; nobody wants to commit their parts to have them plated and receive them back bent and crooked.

However, this seemingly simple wish for evenness is not as easily realized as one might think. “Inner tensions” are known and feared by electroplaters of all kinds.

What are these inner tensions?

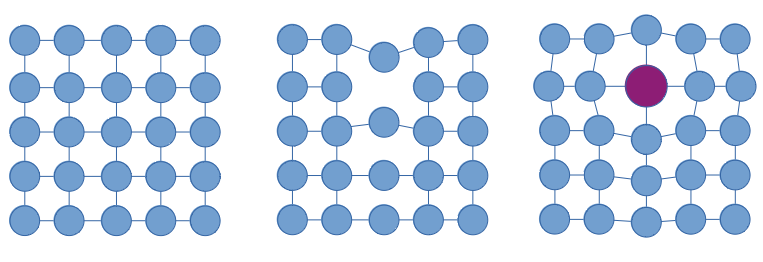

Galvanic layers build up in grid structures. For example, if only copper atoms are deposited, the grid takes a cubic form. However, electrolytes are usually enriched with additives that cause, for example, bright surfaces. Those additives (or even ions that would not belong into the electrolyte in the first place, like nickel) get built into the grid, too. But since they are of different sizes than copper ions the grid structure gets crooked.

It may also happen that places inside the grid structure get skipped, causing flaws in the grid which also lead to distortion.

Inner tensions in metals manifest in two directions:

- Inner tensions of convex alignment (compressive stress)

- Inner tensions of concave alignment (tensile stress)

Bright copper depositions often show the second type of inner tensions, and it’s generally not easy to change this.

What we do for even depositions:

1) Monitoring: We developed internal procedures that allow us to always keep track of inner tensions of our depositions. Therefore, we can adjust electrolytes in a very timely manner.

2) Adaptation of our bath chemistry (link): If inner tensions exceed the norm, the electrolyte in question must be nurtured into shape.

Advantages of galvano-t

Competent expert consulting

Call +49 (0) 2661 - 949 174 (Mon-Thu 8am-3pm, Fri 7.30am-12.30pm) for a free consultation with one of our experts on all kinds of technical issues, such as choosing the best material, options for implementing custom designs, etc.

ISO 9001:2015

Since 2018 we are ISO 9001:2015 certified. Thereby we meet a high standard of quality management systems

30 years of good services

We operate as a manageable, medium-sized company and deliberately keep the hierarchy flat. This philosophy has served us and our customers well for over 30 years.

Request expert advice now

Mon-Thu 8am-15pm / Fri 7.30am-12.30pm

Products

500 Mhz Cavity, Beschleunigungsgitter (NBI), Eingalvanisierte Heizleiter, Faraday Schild, Schabewärmetauscher, Thermoelemente und mehr....

Material

We are specialized in producing components by electroforming. Mainly we process copper and nickel

Procedure

Thin-walled structures, Electroforming on cores, Solderable coatings, Repair of continuous casting molds, Adhesive coating of stainless steels.

Research

We have been involved in various research projects, especially in the fields of nuclear fusion and space research, for 30 years.