Acceleration Grids (NBI)

To heat up plasma in fusion reactors various heating systems can be used. The component we introduce here is part of the neutral injection heating system which heats up plasma inside the torus by firing neutralized protons or deuterons at it.

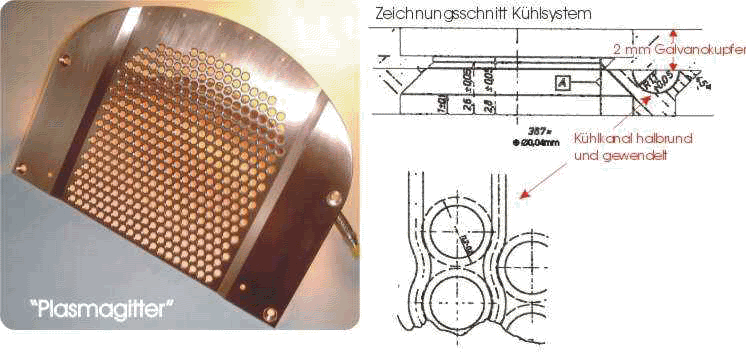

The ion accelerator’s centerpiece consists of a set of extraction grids (3 levels) that extracts and therefore speeds up protons from the plasma source by creating an electrical potential.

In its entirety the ion ray measures 230 x 500 mm and consist of 774 singular rays. Because of its geometry and the highest precision drilling of the extraction bores the rays get focused unto one mutual point 6,5 meters away.

To get through the torus’ magnetic field, the plasma ray has to pass through a neutralizer consisting of neutral gas (H²) where it picks up its fast electrons.

This newly formed “neutral beam” can enter the very depths of the torus’ plasma and release its energy there.

Acceleration grids of this kind are being used in fusion experiments by Asdex Upgrade (IPP-Garching), TEXTOR (Research Institute Julich) and W7X (IPP-Garching/-Greifswald).

Since a lot of protons hit the copper surfaces those need to be cooled intensely.

Operating Data

– Ion beam energy output: 55 keV with an ion flow of 85 A comes down to a beam performance of about 4,5 MW (hydrogen-powered)

– power dissipation (which needs to be cooled) on plasma grid: 250 KW

– Water operating pressure: 16 bar

A leakage rate of better than 10-8 mbar xl/s at a pressure of 16 bar (He) inside the cooling structure is another requirement. And despite such high demands GT has already crafted more than 300 grid halves without noteworthy difficulties.

On top of that we worked on a prototype with IPP Garching to create a grid that accelerates “negative ions”. Those have additional cooling and magnetic channels, as well as electron traps, crafted into them.

Advantages of galvano-t

Competent expert consulting

Call +49 2292 6682 (Mon-Thu 8am-3pm, Fri 7.30am-12.30pm) for a free consultation with one of our experts on all kinds of technical issues, such as choosing the best material, options for implementing custom designs, etc.

ISO 9001:2015

Since 2018 we are ISO 9001:2015 certified. Thereby we meet a high standard of quality management systems

30 years of good services

We operate as a manageable, medium-sized company and deliberately keep the hierarchy flat. This philosophy has served us and our customers well for over 30 years.

Request expert advice now

Mon-Thu 8am-15pm / Fri 7.30am-12.30pm

Products

500 Mhz Cavity, Beschleunigungsgitter (NBI), Eingalvanisierte Heizleiter, Faraday Schild, Schabewärmetauscher, Thermoelemente und mehr....

Material

We are specialized in producing components by electroforming. Mainly we process copper and nickel

Procedure

Thin-walled structures, Electroforming on cores, Solderable coatings, Repair of continuous casting molds, Adhesive coating of stainless steels.

Research

We have been involved in various research projects, especially in the fields of nuclear fusion and space research, for 30 years.