More than Bling: Gold as Technological Material

Gold is a truly unique material that has a lot more to offer than its good looks.

Pure gold is the most ductile metal. It’s even possible to craft gold wires that are as thin as one atomic layer.

It’s the noblest of all metals and only oxidizes under very specific conditions.

It has great electric conductivity (4,5 x 107 S/m) and only gets overshadowed by copper (5,8 x 107 S/m) and silver (6,1 x 107 S/m).

It’s non-toxic and non-irritating.

Gold has excellent reflective properties and works well against electromagnetic radiation (infrared as well as radiowaves and visible light).

It’s very dense (19,2 g/cm³).

Knowing all these facts it’s not surprising that gold finds a lot of applications outside of decorative electroplating.

In most cases you won’t find pure 24 K gold in galvanic layers (although it is possible). To make the gold layer brighter, harder and more even, other substances (like Cobalt) get deposited as well.

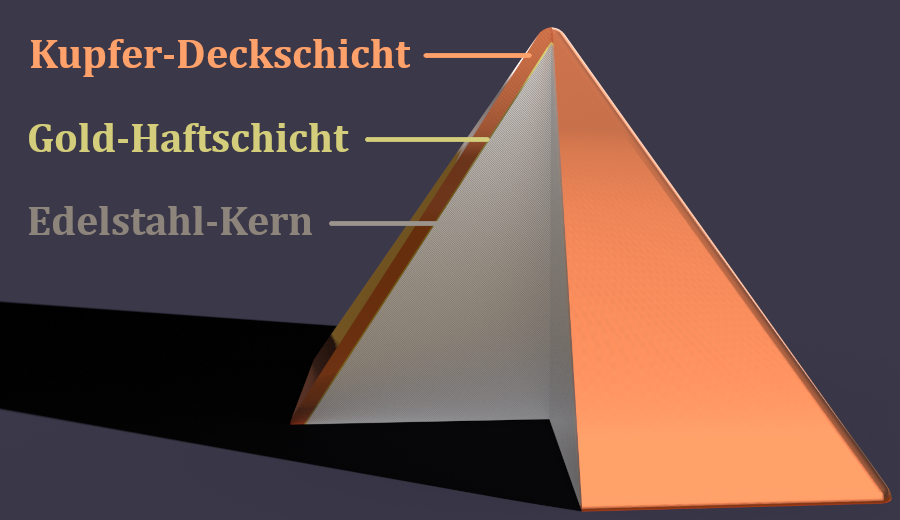

Gold as Bonding layer

Plating stainless steels (and some other metals and metal alloys as well) is usually achieved by using a bonding layer of Nickel before applying the desired metal layer.

However, nickel is ferromagnetic and therefore unusable for certain applicances like measurement and high frequency technology. It also gets increasingly avoided by medicinal technology and the jewelry industry because of its allergenic properties. In cases like these we offer a bonding layer of gold.

Gold with its pretty yellow color also differenciates better from the stainless steel surface than most other metals, making it easier to spot flaws in the bonding layer.

Gold in Space Travel

Because of its reflective abilities and non oxidative properties gold is a most desired material in space travel. Astronaut’s visors, for example, are coated with a thin gold layer that protects them from cosmic radiation without producing a glare.

Advantages of galvano-t

Competent expert consulting

Call +49 2292 6682 (Mon-Thu 8am-3pm, Fri 7.30am-12.30pm) for a free consultation with one of our experts on all kinds of technical issues, such as choosing the best material, options for implementing custom designs, etc.

ISO 9001:2015

Since 2018 we are ISO 9001:2015 certified. Thereby we meet a high standard of quality management systems

30 years of good services

We operate as a manageable, medium-sized company and deliberately keep the hierarchy flat. This philosophy has served us and our customers well for over 30 years.

Request expert advice now

Mon-Thu 8am-15pm / Fri 7.30am-12.30pm

Products

500 Mhz Cavity, Beschleunigungsgitter (NBI), Eingalvanisierte Heizleiter, Faraday Schild, Schabewärmetauscher, Thermoelemente und mehr....

Material

We are specialized in producing components by electroforming. Mainly we process copper and nickel

Procedure

Thin-walled structures, Electroforming on cores, Solderable coatings, Repair of continuous casting molds, Adhesive coating of stainless steels.

Research

We have been involved in various research projects, especially in the fields of nuclear fusion and space research, for 30 years.