Faraday Shield (actively cooled)

To create plasma, the Max Planck Institute for Plasma Physics in Garching uses HF-ion sources. Those are three-walled containers which have an integrated quartz coat and are wrapped with a coil that creates high frequency.

Since the quartz coat is mechanically not stable enough to withstand the inner vacuum, the negative pressure gets adjusted step by step inside the inner walls to normal pressure.

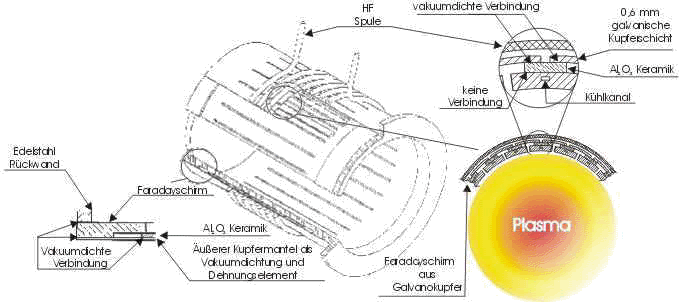

Between plasma and quartz mustn’t be visual contact because the plasma would sputter SiO2 off the coat. This would cast down on other components and disturb the source’s operation. To prevent this a faraday shield is assembled between quartz and plasma.

All in all, this is a complicated design, which makes access to the HF coil (which operates in vacuum) difficult. Therefore, a different design that didn’t have these problems was embraced.

One possible approach turned up during experiments at Galvano-T when Al2O3 ceramics were bonded gas-tight with copper. This allowed for a better design that combined quartz coat (which now became Al2O3 ceramics strips) and faraday shield at a lower wall thickness of 10 mm.

By offsetting bridges and ceramic strips, the Al2O3 is not “visible” to the plasma, protecting it from sputtering. Also, the corpus that gets heated by plasma and HF eddy currents can be cooled completely now with only few additional expenditures.

A prototype, a scaled down model of the ion source, already successfully generated plasma.

The current goal is testing the prototype at real-life conditions until the construction of a 1:1 ion source can be started.

Advantages of galvano-t

Competent expert consulting

Call +49 2292 6682 (Mon-Thu 8am-3pm, Fri 7.30am-12.30pm) for a free consultation with one of our experts on all kinds of technical issues, such as choosing the best material, options for implementing custom designs, etc.

ISO 9001:2015

Since 2018 we are ISO 9001:2015 certified. Thereby we meet a high standard of quality management systems

30 years of good services

We operate as a manageable, medium-sized company and deliberately keep the hierarchy flat. This philosophy has served us and our customers well for over 30 years.

Request expert advice now

Mon-Thu 8am-15pm / Fri 7.30am-12.30pm

Products

500 Mhz Cavity, Beschleunigungsgitter (NBI), Eingalvanisierte Heizleiter, Faraday Schild, Schabewärmetauscher, Thermoelemente und mehr....

Material

We are specialized in producing components by electroforming. Mainly we process copper and nickel

Procedure

Thin-walled structures, Electroforming on cores, Solderable coatings, Repair of continuous casting molds, Adhesive coating of stainless steels.

Research

We have been involved in various research projects, especially in the fields of nuclear fusion and space research, for 30 years.