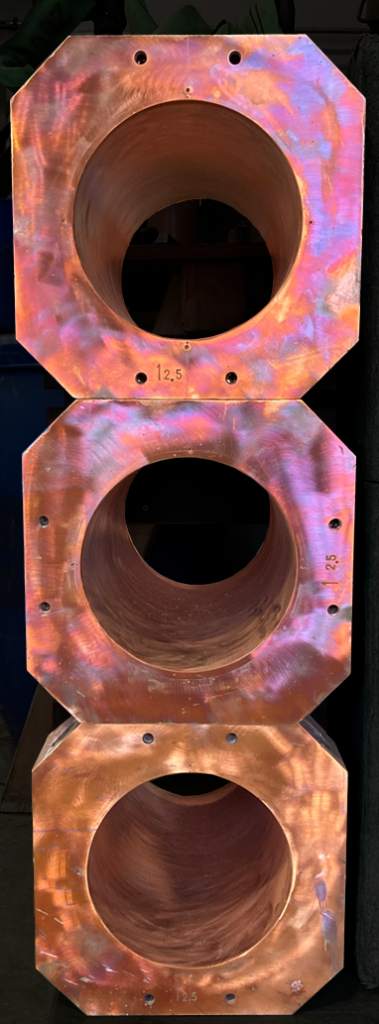

Repair of Continuous Casting Molds

The life of a steel profile begins with the continuous molding of molten steel through a vertically positioned formative pipe-, block- or slab-mold made from copper.

This copper mold gets cooled externally. It is constructed in a way that makes the outgoing steel profile slightly bend (by a radius of 6-10 meters) and thus can be trundled into a horizontal position.

The mold’s length preferably is between 500 and 1000 mm to ensure the cooling, and therefore shaping of the molten steel. However, if steel goes from its liquid to its solid state, it shrinks. This could mean that it loses contact to the mold wall and breaks through its thin, solid outer skin. To avoid that the mold’s interior has a conicity of 1,1%.

If the casting gets interrupted for productional reasons, the residual steel is left to cool off and solidify. Alternatively, a plug is gets inserted before the next casting. In any case, the casting mold’s wall gets damaged in its solid area.

Over time the damages sum up and the casting mold becomes unusable because the contact to the steel wall becomes insufficient.

A repair for certain, smaller, formats (130 x 140 mm) aren’t worth the repair. They are produced in large quantities and get thrown out after.

If they follow a more complex design or simply have larger dimensions a galvanic repair often proves to be beneficial.

The damaged mold cast gets de-chromed, activated, and receives a coat of 2-5 mm on its inner wall. The damages get filled up with copper and after some machining the cast mold returns to its former glory, having the same inner contour of its original design. This process can be repeated infinitely.

Advantages of galvano-t

Competent expert consulting

Call +49 2292 6682 (Mon-Thu 8am-3pm, Fri 7.30am-12.30pm) for a free consultation with one of our experts on all kinds of technical issues, such as choosing the best material, options for implementing custom designs, etc.

ISO 9001:2015

Since 2018 we are ISO 9001:2015 certified. Thereby we meet a high standard of quality management systems

30 years of good services

We operate as a manageable, medium-sized company and deliberately keep the hierarchy flat. This philosophy has served us and our customers well for over 30 years.

Request expert advice now

Mon-Thu 8am-15pm / Fri 7.30am-12.30pm

Products

500 Mhz Cavity, Beschleunigungsgitter (NBI), Eingalvanisierte Heizleiter, Faraday Schild, Schabewärmetauscher, Thermoelemente und mehr....

Material

We are specialized in producing components by electroforming. Mainly we process copper and nickel

Procedure

Thin-walled structures, Electroforming on cores, Solderable coatings, Repair of continuous casting molds, Adhesive coating of stainless steels.

Research

We have been involved in various research projects, especially in the fields of nuclear fusion and space research, for 30 years.