Properties | Method | Intervall |

Optical properties (brightness etc) | Concurrent Sample | Daily |

Hullcell Sheet | Weekly | |

Inner Tension | Concurrent Sample | Daily |

Testing strips that get exposed to different electric currents | Weekly | |

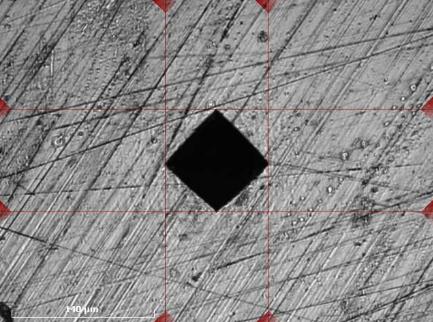

Hardness | Brinell/Vickers | If required |

Bonding | Quench-Test & Breaking-Test (plus visual assessment under a stereo microscope) | Before usage of bonding baths |

Contents of Metal/Acid/Chloride | Titrimetric Test | Weekly |

pH and Temperature | pH-Meter / Thermometer | Daily |

Other parameters, for example ductility need to be tested at an external institute.

Special Methods for Testing Tensile Strength

While most of our analytical methods are conventional, we had to be more creative about tensile strength. The conventional method would require us to send in samples on a near daily basis, because bath parameters can change quickly under certain circumstances.

Especially with thicker layers the control of tensile strength is very important to avoid deformation of base parts.

Which is why we evaluate a concurrent sample every day on a self-developed measuring tool for convexity/concavity of the sample.

Also, on a weekly basis, we test the baths’ depositions at different electric currents.