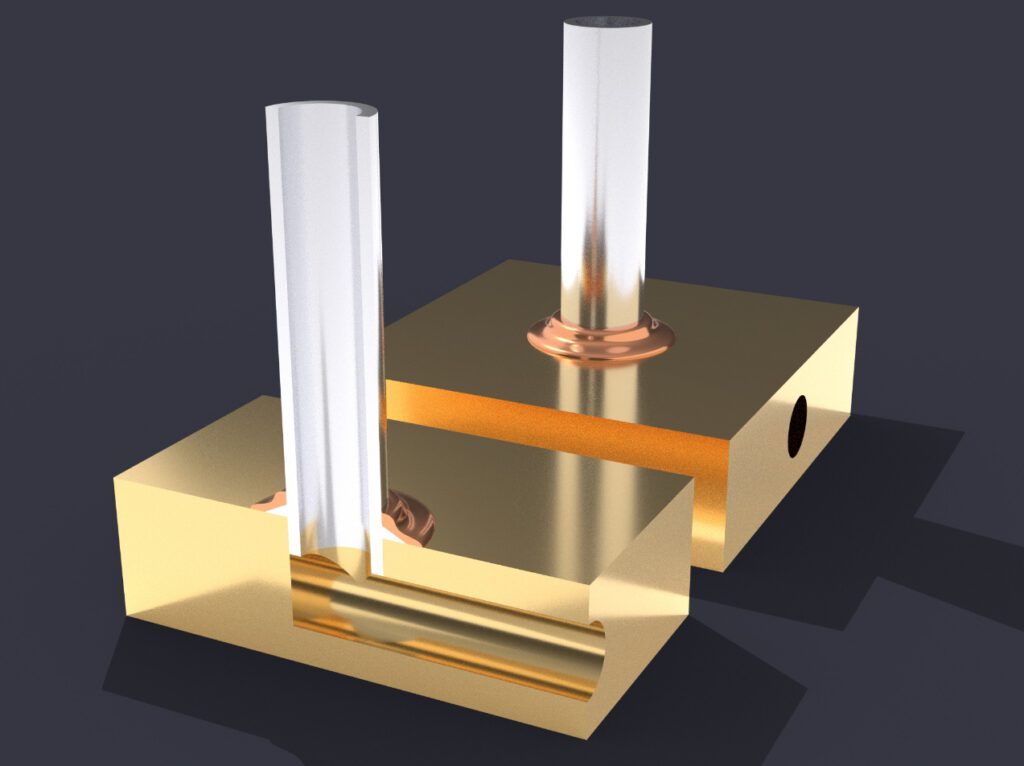

Galvanic Joining of Components

Do you want to join two components into one functional unit but conventional joining methods like soldering, welding and press joining don’t meet your expectations?

Galvanic joining might be what you’re looking for.

Pros:

1.) NO heat input (process happens at room temperature)

2.) Constructive process (excesses can be skimmed or milled off)

3.) Compatible with UHV (Ultra High Vacuum)

Cons:

1.) Galvanic joining often takes several days

2.) Components need to be preprocessed

3.) Electrolytes are usually corrosive, therefore all surfaces that aren’t supposed to get plated need to be covered carefully

How does galvanic joining work?

As usual in electroplating the process is closely connected to the materials that need to be joined. Stainless steel components, for example, need a different treatment than copper components. If two different materials need to be joined the process gets even more complex.

Whatever the material, every part of the surface that isn’t supposed to get plated, needs to get covered carefully. Afterwards the exposed surface must be degreased and pickled, and the rest of the preprocessing can follow. Stainless steel for example often gets plated with a Nickel Strike

layer before the actual coating (usually copper) is added on top. To apply that top layer the components either get galvanized inside one of our baths or we attach miniature baths to them that are then filled with electrolyte. This allows us to plate objects that are too big to fit into our galvanic baths or can’t be immersed in electrolyte for other reasons.

Projects in which we made use of galvanic joining

• Joining of stainless-steel connectors to copper baseplates

• Appliance of corner plates to a base plate

• Reinforcement of preexisting welding seams

Do you have further questions about galvanic joining? Or do you want to know if it could enrich your own project? Give us a call or contact us via Email

Advantages of galvano-t

Competent expert consulting

Call +49 2292 6682 (Mon-Thu 8am-3pm, Fri 7.30am-12.30pm) for a free consultation with one of our experts on all kinds of technical issues, such as choosing the best material, options for implementing custom designs, etc.

ISO 9001:2015

Since 2018 we are ISO 9001:2015 certified. Thereby we meet a high standard of quality management systems

30 years of good services

We operate as a manageable, medium-sized company and deliberately keep the hierarchy flat. This philosophy has served us and our customers well for over 30 years.

Request expert advice now

Mon-Thu 8am-15pm / Fri 7.30am-12.30pm

Products

500 Mhz Cavity, Beschleunigungsgitter (NBI), Eingalvanisierte Heizleiter, Faraday Schild, Schabewärmetauscher, Thermoelemente und mehr....

Material

We are specialized in producing components by electroforming. Mainly we process copper and nickel

Procedure

Thin-walled structures, Electroforming on cores, Solderable coatings, Repair of continuous casting molds, Adhesive coating of stainless steels.

Research

We have been involved in various research projects, especially in the fields of nuclear fusion and space research, for 30 years.