Corrugated Horns without Cavities

Special corrugated horns are components needed for the reception of radio telescopes. The above-mentioned horn is a feed aerial for the secondary focus of the Effelsberger radio telescope. With a diameter of 100 meters this telescope is the largest fully movable antenna on earth.

The parabolic reflector catches space radiation at 23 GHz and reflects it on a second elliptically formed reflector that shares one of the focal points of the parabol and reflects it towards the second focal point.

The corrugated horn is mounted at the second focal point as an energy collector. This means that the horn is the actual antenna that leads the collected energy towards the following sensitive receiver system.

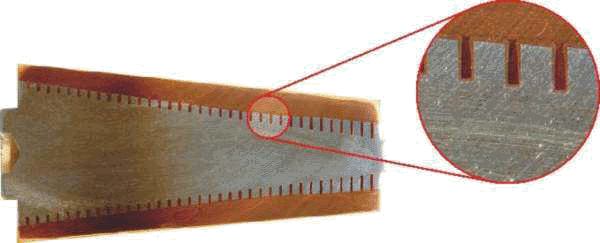

These corrugated horns have a complex geometric build that is very hard, or even impossible, to craft by the means of machining.

Thanks to Galvano-forming we may offer a cost-efficient solution for this problem. Together with the MPI for radio astronomy in Bonn we designed a process to craft complex corrugated horns with an extremely high relation of keyway depth to keyway width (6:1).

Starting from the base body of a mechanically well workable aluminum alloy (e.g., AlMgSi0,5) the later bridges were turned into it as keyways. The horn is created by depositing either a thick layer of copper or nickel. Certain processes avoid that leftover electrolyte stays inside the keyways which could later lead to corrosion. Depending on the horns size and geometry the plating process gets interrupted at about 2,5 mm so that flanges and reinforcements can be applied and, afterwards, plated into the horn.

Advantages of galvano-t

Competent expert consulting

Call +49 2292 6682 (Mon-Thu 8am-3pm, Fri 7.30am-12.30pm) for a free consultation with one of our experts on all kinds of technical issues, such as choosing the best material, options for implementing custom designs, etc.

ISO 9001:2015

Since 2018 we are ISO 9001:2015 certified. Thereby we meet a high standard of quality management systems

30 years of good services

We operate as a manageable, medium-sized company and deliberately keep the hierarchy flat. This philosophy has served us and our customers well for over 30 years.

Request expert advice now

Mon-Thu 8am-15pm / Fri 7.30am-12.30pm

Products

500 Mhz Cavity, Beschleunigungsgitter (NBI), Eingalvanisierte Heizleiter, Faraday Schild, Schabewärmetauscher, Thermoelemente und mehr....

Material

We are specialized in producing components by electroforming. Mainly we process copper and nickel

Procedure

Thin-walled structures, Electroforming on cores, Solderable coatings, Repair of continuous casting molds, Adhesive coating of stainless steels.

Research

We have been involved in various research projects, especially in the fields of nuclear fusion and space research, for 30 years.